| Features |

Mamos technical data | Ordering Guide | Component Specifications & Add Ons |

1. General parameters – analyser unit

| Dimensions (W x H x D) | 240mm x 360mm x 160mm |

| Weight (depends on equipment) | 4kg - 5kg |

| Casing's material | ABS |

| Protection grade | IP20 |

| Mounting plate: dimensions (H x W) | material | weight | 596mm x 450mm | aluminium | 1.9kg |

| Operating conditions | T: 10°C - 50°C, RH: 5% - 90% (non-condensing) |

| Storing temperature | 0°C - 55°C |

| Power consumption (analyser unit only) | 30W max |

| Data-logger: type | size | number of results | SD flash card | max 4GB | practically unlimited |

| Display: type | parameters | Backlit LCD | 20 characters x 4 lines |

| Gas pump: type | max gas flow | standard gas flow | Diaphragm | max 2l/min | 1.5l/min (90l/h) |

| Maximal extraction point pressure: | Atmospheric ±200hPa |

| Current analogue outputs | 4 outputs 0mA - 20mA or 4mA - 20mA |

| Voltage analogue outputs | 4 outputs 0V - 5V or 0V - 10V |

| Digital inputs | 2 inputs, TTL levels, floating = high level |

| Digital outputs | 1 open collector output + 2 SPDT relays (optional) |

| Computer communication interface | B type USB socket |

2. General parameters – power supply unit

| Dimensions (W x H x D) | 360mm x 130mm x 56mm |

| Weight (depends on equipment) | 1.4kg |

| Casing's material | aluminium |

| Mounting plate | Power supply is mounted on common plate with analyser unit |

| Operating conditions | T: +10°C - +50°C, RH: 5% - 90% (non-condensing) |

| Storing temperature | -20°C - +55°C |

| Input voltage | 100 - 240V AC 50/60Hz |

| Output voltage | 24V DC / 6.3A | 150W |

| Output current | 6.3A max |

| Mains fuse | 6A |

| Cable pass | 2 pcs PG-9 |

3. Gas dryer - MD2 gas dryer

| Dimensions (W x H x D) | 211mm x 74mm x 82mm |

| Weight | 450g |

| Drying method | Water condensation by rapid cooling down |

| Cooler type | Based on Peltier cooling element with fan (7VDC supply) |

| Cooling temperature | Down to +4°C electronically stabilised Dew point of outlet gas 8°C below the temperature of inlet gas. |

| Ready to operate after | 10 minutes |

| Operating conditions | T: 0°C - 35°C, RH: 5% - 90% (non-condensing) |

| Storing temperature | -20°C - 60°C |

| Maximum gas flow for efficient drying (at inlet gas temp. 100°C and RH 100%) |

40l/h |

| Gas filter | Integrated, with condensate reservoir and replaceable insert |

| Filter insert: length | ID | OD | material | pore size | 32mm | 15mm | 20mm | PE | 5µm |

| Condensate removal | With peristaltic pump installed in analyser's body |

| Peristaltic pump capacity | 38ml/min |

| Power supply | Via maMoS (through 15-pin D-SUB connector) |

| Power consumption | 9W |

4. Gas dryer - MD3 gas dryer

| Dimensions (W x H x D) |

|

||||

| Weight | 1790g (single filter version) | ||||

| Drying method | Water condensation by rapid cooling down | ||||

| Cooler type | Based on Peltier cooling element with fan (12VDC supply) | ||||

| Cooling temperature | Constant, about +1°C, output gas dewpoint about +4°C | ||||

| Ready to operate after | 5 minutes | ||||

| Operating conditions | T: 0°C - 50°C, RH: 5% - 90% (non-condensing) | ||||

| Storing temperature | -20°C ÷ 60°C | ||||

| Maximum gas flow for efficient drying (at inlet gas temp. 100°C and RH 100%) |

100l/h | ||||

| Gas filters: quantity | material | 1 (optionally 2) | PA – body, PC – cover, viton – sealing | ||||

| Filter insert: length | ID | OD | material | pore size | 42mm | 26mm | 32mm | glass fibre | 2µm | ||||

| Power supply | Standard: via maMoS power supply (through 3-wire power cable) Standalone version via external supply module: 85V - 264V AC / 24V DC |

||||

| Condensate removal | With built-in peristaltic pump | ||||

| Peristaltic pump capacity | 38ml/min | ||||

| Power consumption | 30W |

5. Measurements of gas components

Table below shows the combination of all sensors/ranges. Please note that the maximum number of sensors allowed is 8, per unit.

| Component | Method | Range | resolution | Accuracy | Time (T90) | Conformity |

| O2 – Oxygen | Electrochemical, partial pressure | 20.95% | 0.01% | ± 0.1% abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| O2 – Oxygen | Electrochemical, partial pressure | 25.00% | 0.01% | ± 0.1% abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| O2 – Oxygen | Electrochemical, partial pressure | 100.00% | 0.1% | ± 0.1% abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO – Carbon monoxide | Electrochemical sensor | 4 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO – Carbon monoxide | Electrochemical, with H2 compensation | 4 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO – Carbon monoxide | Electrochemical sensor | 20 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO – Carbon monoxide | Electrochemical, with H2 compensation | 20 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO – Carbon monoxide | Electrochemical sensor | 10% | 0.001% | ± 0.005% abs. or 5% rel. | 45 sec | ISO 12039, CTM-030 |

| CO – Carbon monoxide | NDIR | 10% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | EN 15058,Method 10 |

| CO – Carbon monoxide | NDIR | 25% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | EN 15058,Method 10 |

| CO – Carbon monoxide | NDIR | 50% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | EN 15058,Method 10 |

| CO – Carbon monoxide | NDIR | 100% | 0.1% | ± 0.5% abs. or 5% rel. | 45 sec | EN 15058,Method 10 |

| CO2 – Carbon dioxide | NDIR | 5% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | ISO 12039,OTM-13 |

| CO2 – Carbon dioxide | NDIR | 10% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | ISO 12039,OTM-13 |

| CO2 – Carbon dioxide | NDIR | 25% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | ISO 12039,OTM-13 |

| CO2 – Carbon dioxide | NDIR | 50% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | ISO 12039,OTM-13 |

| CO2 – Carbon dioxide | NDIR | 100% | 0.1% | ± 0.5% abs. or 5% rel. | 45 sec | ISO 12039,OTM-13 |

| CxHy – Total Hydrocarbons | NDIR | 1% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | |

| CxHy – Total Hydrocarbons | NDIR | 5% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | |

| CxHy – Total Hydrocarbons | NDIR | 10% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | |

| CxHy – Total Hydrocarbons | NDIR | 25% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | |

| CxHy – Total Hydrocarbons | NDIR | 50% | 0.01% | ± 0.05% abs. or 5% rel. | 45 sec | |

| CxHy – Total Hydrocarbons | NDIR | 100% | 0.1% | ± 0.5% abs. or 5% rel. | 45 sec | |

| NO – Nitric oxide | Electrochemical sensor | 1 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 45 sec | CTM-022 |

| NO – Nitric oxide | Electrochemical sensor | 5 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 45 sec | CTM-022 |

| NO2 – Nitrogen dioxide | Electrochemical sensor | 1 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 60 sec | CTM-022 |

| NO2 – Nitrogen dioxide | Electrochemical sensor | 4 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 60 sec | CTM-022 |

| SO2 – Sulphur dioxide | Electrochemical sensor | 2 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 45 sec | |

| SO2 – Sulphur dioxide | Electrochemical sensor | 5 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 45 sec | |

| H2S – Hydrogen sulfide | Electrochemical sensor | 1 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 70 sec | |

| H2S – Hydrogen sulfide | Electrochemical sensor | 10 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 45 sec | |

| H2 – Hydrogen | Electrochemical sensor | 2 000ppm | 1ppm | ± 10ppm abs. or 5% rel. | 50 sec | |

| H2 – Hydrogen | Electrochemical sensor | 20 000ppm | 1ppm | ± 10ppm abs. or 5% rel. | 70 sec | |

| H2 – Hydrogen | Thermal Conductivity Detector | 10% | 0.1% | ± 0.5% abs. or 5% rel. | 45 sec | |

| H2 – Hydrogen | Thermal Conductivity Detector | 25% | 0.1% | ± 0.5% abs. or 5% rel. | 45 sec | |

| H2 – Hydrogen | Thermal Conductivity Detector | 50% | 0.1% | ± 0.5% abs. or 5% rel. | 45 sec | |

| H2 – Hydrogen | Thermal Conductivity Detector | 100% | 0.1% | ± 0.5% abs. or 5% rel. | 45 sec | |

| N2O – Nitrous oxide | NDIR | 2 000ppm | 1ppm | ± 10ppm abs. or 5% rel. | 45 sec | ISO 21258 |

| N2O – Nitrous oxide | NDIR | 5 000ppm | 1ppm | ± 10ppm abs. or 5% rel. | 45 sec | ISO 21258 |

| CHF3 – Fluoroform (Refrigerant R23) | NDIR | 2.5% | 0.01% | ± 0.05 abs. or 5% rel. | 45 sec | |

| CL2 - Chlorine | Electrochemical sensor | 250ppm | 1ppm | ± 5ppm abs. or 5% rel. | 60 sec | |

| VOC - Volatile Organic compounds | PID - Photo Ionization Detector | 100ppm | 1ppm | ± 5ppm abs. or 5% rel. | 120 sec | Method 21 |

| VOC - Volatile Organic compounds | PID - Photo Ionization Detector | 1 000ppm | 1ppm | ± 5ppm abs. or 5% rel. | 120 sec | Method 21 |

4. Other measurements / calculated results

| Variable | Method | Range | resolution | Accuracy | Time (T90) |

| Tgas – gas temperature | K-type thermocouple | -50 - 1000°C | 0.1°C | ± 2°C | 10 sec |

| Tgas – gas temperature | S-type thermocouple | -50 - 1500°C | 0.1°C | ± 2°C | 10 sec |

| Tamb – boiler intake air temperature | PT500 resistive sensor | -50 - 100°C | 0.1°C | ± 2°C | 10 sec |

| Differential pressure | Silicon piezoresistive pressure sensor | -25hPa - 25hPa | 1Pa (0.01hPa) | ± 2Pa abs. or 5% rel. | 10 sec |

| Gas flow velocity | Indirect, with Pitot tube & pressure sensor | 1 - 50m/s | 0.1m/s | 0.3m/s abs. or 5% rel. | 10 sec |

| Lambda λ – excess air number | Calculated | 1 - 10 | 0.01 | ± 5% rel. | 10 sec |

| qA – stack loss | Calculated | 0 - 100% | 0.1% | ± 5% rel. | 10 sec |

| Eta η – combustion efficiency | Calculated | 0 - 120% | 0.1% | ± 5% rel. | 10 sec |

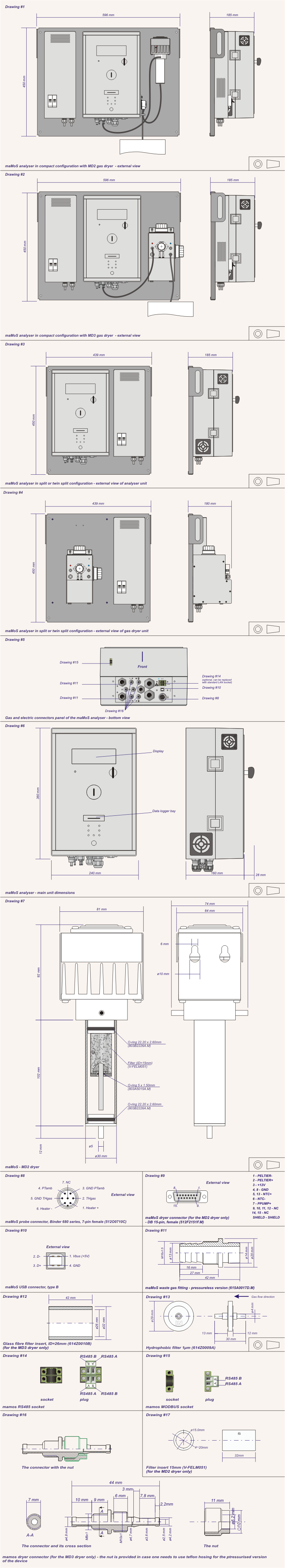

Drawings