Fixed Gas Detectors

Continuous Single Gas Detection

Applications :

- Oil refineries

- Mining

- Chemical plants

- Food industry

- Water water treatment plants

PQ Series Fixed Gas Detectors

PQD Series With Digital Display

Features :

- Multiple Gas Sensor Options

- OLED Display

- Standard 4-20mA Output

- Standard RS485 Modbus(RTU) Interface

- Optional 3 Relay Outputs(Alarm1,Alarm2 and Fault)

- Standard Epoxy Painted Aluminium Body

- Optional SS316 Stainless Steel Body

- Standard Stainless Steel Sensor Housing

- 1/2'',3/4 NPT and M20 Cable Entry Options

- IP65/ IP66 Protection Class

- Suitable to operate in Zone 1, Zone 2 and M2

- ATEX Marking : II 2G Ex db IIC T6 Gb, II 2G Ex mb db IIC T6 Gb, I M2 Ex db I Mb

- Hazardous class : Zone 1 - Zone 2 - M2

- Certificates : ExVeritas 18 ATEX 0371X, IECEx EXV 18.0021X, FTZU 18 ATEX 0086, IEP12 ATEX 6118X, SIL2

- Standards : IEC EN 60079-0, IEC EN 60079-1, IEC EN 60079-18mm, IEC EN 60079-29-1

User Friendly Software

- Magnetic Control

- Calibration Due Warning

- Non-Intrusive Calibration

- Data Logging (Safelog)

- Continuous Self-Test

- Analog Output Simulation

- Relay Test

- Bump Test

- Adjustable Parameters

- Calibration Interval

- Zero Suppression

- Gas Concentration Trends

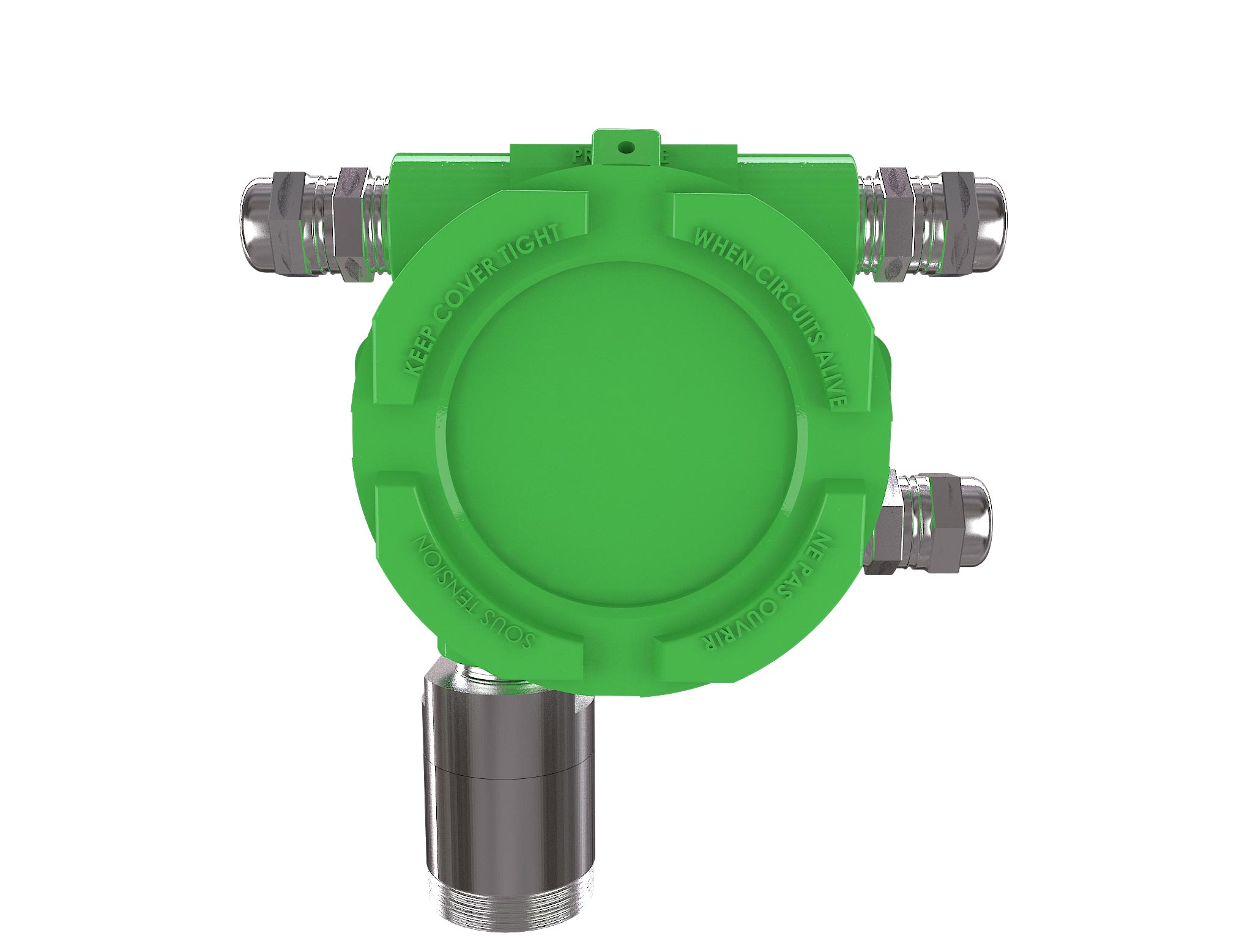

PQN Series Without Digital Display

Features :

- Pellistor (Catalytic), Electrochemical, Infrared Sensor Options

- Standard 4-20mA Output

- Standard RS485 Modbus(RTU) Interface

- Optional 3 Relay Outputs(Alarm1, Alarm2, and Fault)

- Standard Epoxy Painted Aluminium Body

- Optional SS316 Stainless Steel Body

- Standard Stainless Steel Sensor Housing

- 1/2'',3/4 NPT and M20 Cable Entry Options

- IP65/ IP66 Protection Class

- Suitable to operate in Zone 1, Zone 2 and M2

- ATEX Marking : II 2G Ex db IIC T6 Gb, II 2G Ex mb db IIC T6 Gb, I M2 Ex db I Mb

- Hazardous class : Zone 1 - Zone 2 - M2

- Certificates : ExVeritas 18 ATEX 0371X, IECEx EXV 18.0021X, FTZU 18 ATEX 0086, IEP12 ATEX 6118X, SIL2

- Standards : IEC EN 60079-0, IEC EN 60079-1, IEC EN 60079-18mm, IEC EN 60079-29-1

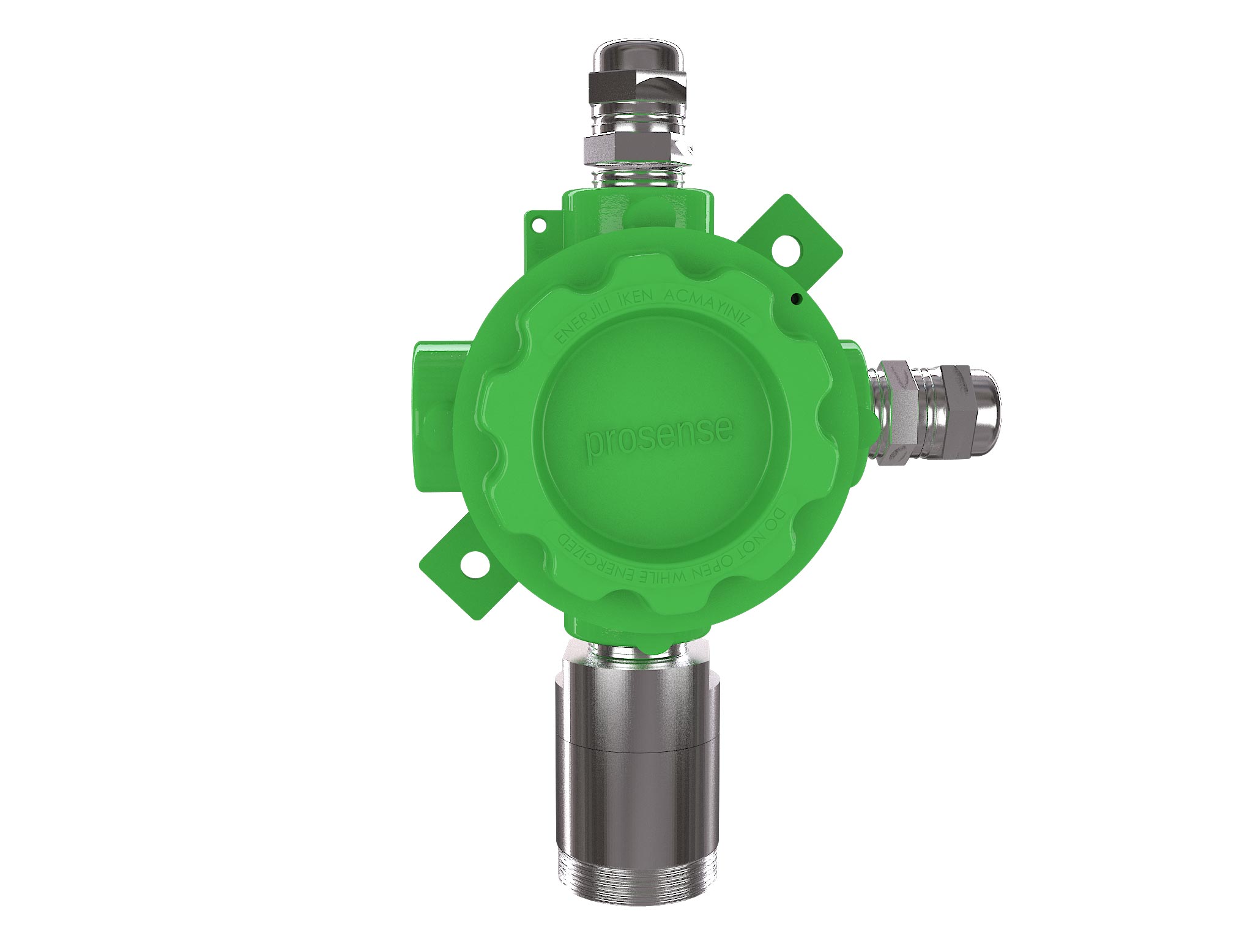

P Series Gas Detectors

Features :

- Pellistor (Catalytic), Electrochemical, Infrared Sensor Options

- Standard 4-20mA Output

- Standard RS485 Modbus(RTU) Interface

- Optional Relay Outputs (Alarm1, Alarm2, and Fault)

- Die-cast aluminium enclosure

- Stainless Steel Sensor Housing

- 1/2'' NPT Cable Gland

- IP65/ IP66

- ATEX Marking : II 2G Ex db IIC T5/T4 Gb

- Hazardous class : Zone 1 or Zone 2

- Certificates : IMQ 19 ATEX 045 X, IECEx IMQ 18.0009X

- Standards : IEC EN 60079-0, IEC EN 60079-1, IEC EN 60079-18

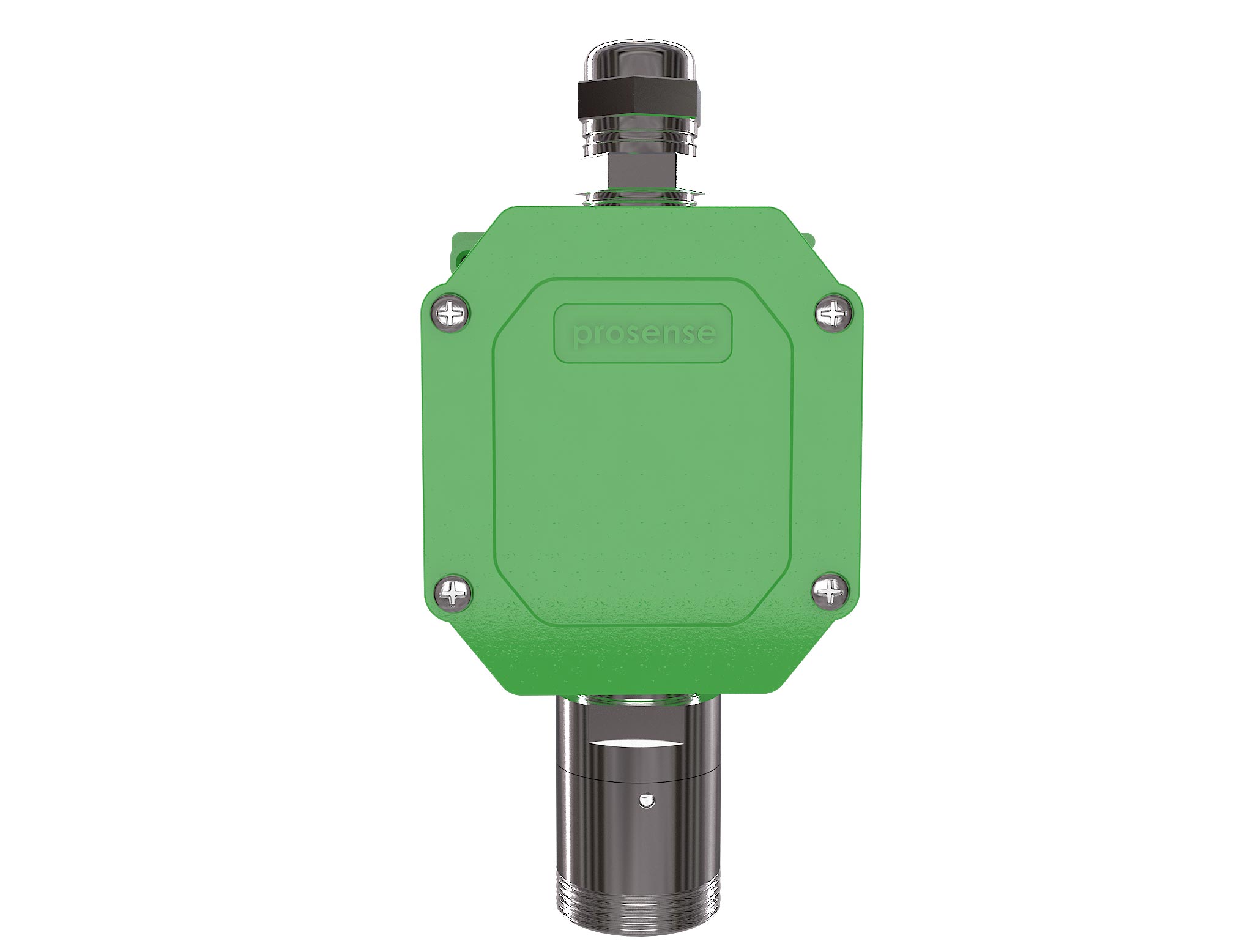

PC3 Series

Features :

- Catalytic, Electrochemical Sensor Options

- Standard 4-20mA Output

- Standard Modbus RS485(Interface) Output

- Optional Relay Outputs(Alarm1, Alarm2, and Fault)

- Die-cast aluminium enclosure

- 1/2'' NPT Cable Entry

- IP65, Zone 2

- Hazardous Class : Zone 2 ‐ Category 3

- Standards : EN 60079-0, EN 60079-1, EN 60079-18

SOMA Series

Intrinsically Safe for continuous measurement of toxic and explosive gases in a hazardous environment

Features :

- Pellistor(Catalytic), Electrochemical, Infrared Sensor Options

- LCD Display

- Standard 4-20mA Output

- Standard RS485 Modbus(RTU) Interface

- ABS Plastic Body

- 2x M20 Cable Entries

- IP65 Protection Class

- Suitable to operate in M1 applicaitons

- ATEX Marking: Ex ia I Ma

Safe Vader Series

For use in safe areas for continuous measurement of toxic and flammable gases and Oxygen

Features :

• Standard 4-20mA Output

• Standard Modbus RS485(Interface) Output

• Standard Relay Outputs(Alarm1, Alarm2, and Fault)

• ABS Plastic